How Dirty HVAC Coils Quietly Destroy Efficiency and Air Quality

Share

Commercial HVAC units are usually tucked away, often on rooftops, so their appearance isn’t usually top of mind. Although this isn’t necessarily a bad thing, it often means facility managers and owners don’t realize how dirty their evaporator coils are.

When they’re neglected, dirty coils can seriously affect comfort, air quality and operating costs. Dirty coils are frequently found in commercial environments where units are exposed to the elements and don’t receive routine maintenance.

Unlike sudden mechanical breakdowns, coil contamination causes gradual performance loss that can be hard to detect until your tenants, customers or employees begin complaining about poor AC performance.

The Role of Coils in HVAC System Performance

Your HVAC system uses two types of coils to control indoor temperature.

- Evaporator coils, located indoors, absorb heat from the air during the cooling process.

- Condenser coils, typically found in outdoor units, release that heat back into the environment.

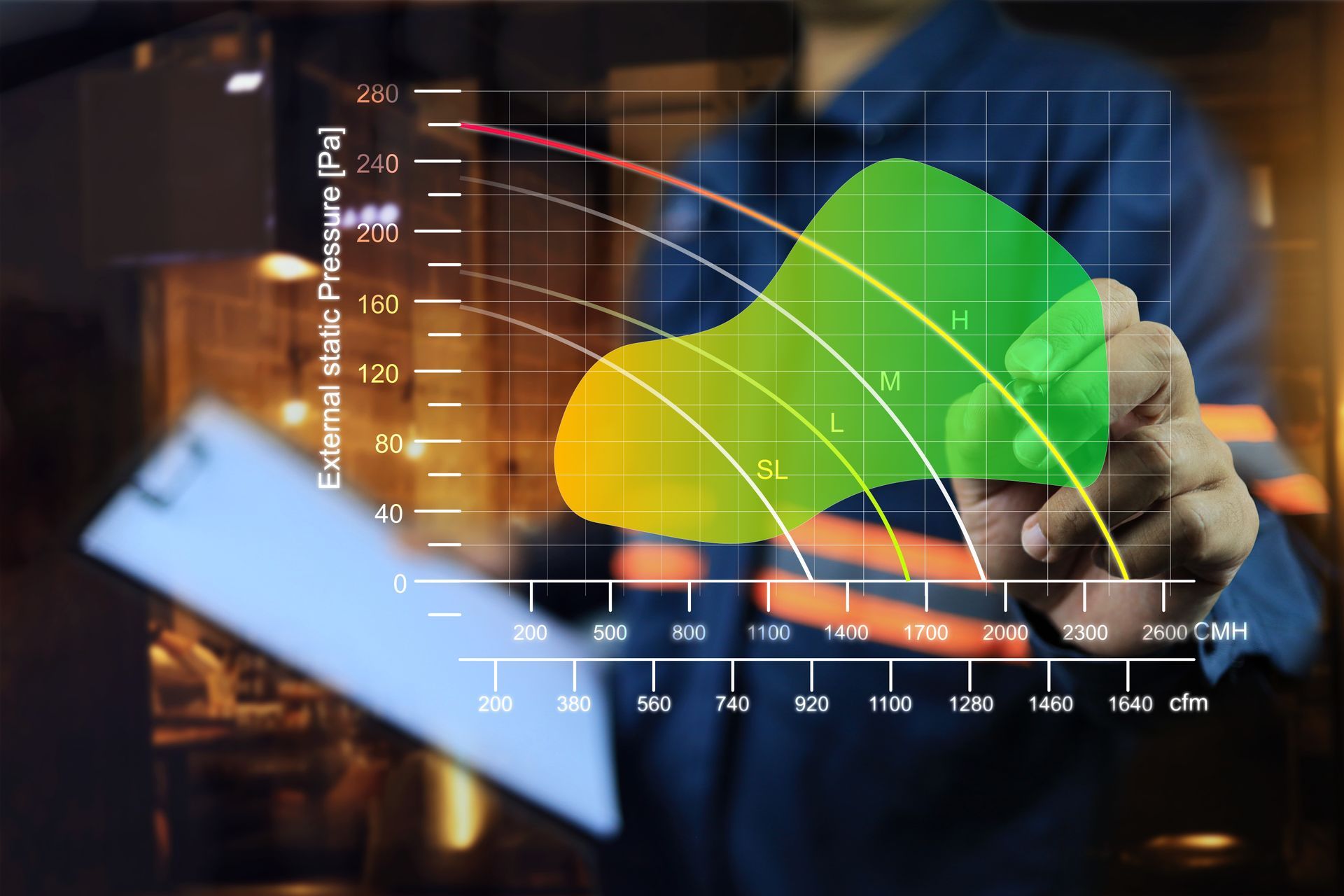

When either coil becomes dirty or coated with debris and grime, the heat transfer process becomes less efficient. That reduced efficiency forces the system to run longer cycles to reach set temperatures, increasing wear on components and driving up energy bills.

Why Coil Contamination Happens

Commercial rooftop units (RTUs) operate in harsh conditions. Windblown dust, soot, pollen and industrial particulates collect on condenser coils throughout the year. Condenser coils are also exposed to leaves, bird droppings and even grease vapors in urban areas or near restaurants.

Indoors, evaporator coils can accumulate dust and moisture over time, especially when filters aren’t changed regularly or when airflow is restricted.

Poor ventilation design or overcrowded mechanical rooms can make the problem worse. In buildings with high occupancy or equipment-generated heat, dirty coils can quickly throw off the system’s load balance.

Symptoms of Dirty Coils

Unlike a unit that won’t start or a leaking refrigerant line, dirty coils don’t always announce themselves with an obvious problem. Instead, performance declines gradually, making it harder to pinpoint the cause. Some warning signs include:

- Rising energy usage despite no changes in building occupancy

- Weak airflow at supply vents

- Unusual or persistently high indoor humidity

- Zones that consistently feel too warm or too cold

- Short cycling or long recovery times after setbacks

Left unaddressed, dirty coils can eventually cause the system to overheat, ice up or trip safety controls, leading to expensive repairs and downtime.

Air Quality and Occupant Health Risks

Evaporator coils exposed to high humidity and dust are ideal environments for bacterial buildup and other organic contaminants. Once embedded in the coil fins, these pollutants can be hard to remove without proper cleaning. As air continues to move across the coils, contaminants may recirculate through the duct system and throughout the building.

Poor indoor air quality can trigger complaints from occupants, especially in schools, office buildings or medical facilities where clean air is essential. If filters are undersized or overdue for replacement, the risk of contaminant recirculation increases dramatically.

How Often Should Coils Be Cleaned?

- At a minimum, condenser coils should be inspected and cleaned at least once per year, preferably before peak cooling season.

- Evaporator coils may require cleaning every one to two years, depending on filter quality and indoor conditions.

- Facilities in dusty or industrial areas may need more frequent service.

Preventive cleaning helps restore proper heat exchange, lowers static pressure in the system and reduces the likelihood of compressor failure.

Can Coil Issues Be Fixed Without Replacing Equipment?

In many cases, yes. Coil cleaning can restore lost efficiency and postpone the need for major repairs or replacement. A trained HVAC technician will inspect the coils for buildup, corrosion and damage, then use chemical cleaners or pressurized rinsing to remove contaminants without damaging the fins. If coil cleaning reveals deeper issues, like refrigerant leaks or airflow problems, those can be addressed at the same time.

Coil Condition is Important for Commercial Properties in Arlington

Dirty HVAC coils might not cause immediate shutdowns, but they’re one of the leading causes of efficiency loss in commercial buildings.

Your HVAC maintenance provider should check your coils during visits and clean them when necessary. Unfortunately, many commercial HVAC companies fail to adhere to maintenance contracts, showing up only once or twice a year when they initially agreed to quarterly visits.

If your maintenance provider is neglecting your property’s systems, and you’re concerned about the efficiency and performance of your units, call Tom’s Commercial. We can provide a full HVAC performance evaluation, including coil inspections, refrigerant checks and airflow balancing.

If your building hasn’t had a coil cleaning in the last 12 months, now is the time to get on a preventive maintenance schedule. Call 817-857-7400 to schedule your service.