How to Tell If Your Commercial HVAC Unit Is Working Properly

Share

For building and facility managers, ensuring a commercial HVAC system runs efficiently is crucial for maintaining comfort, air quality and energy efficiency. You can identify and address issues more quickly and prevent serious damage by watching out for any changes in the system’s operation and performance.

Listen for Unusual Noises

A well-functioning HVAC system should run relatively quietly, producing only the sound of air flowing through the vents and the occasional hum of the unit cycling. New or unusual noises can indicate problems, such as:

- Banging or clanking – Could mean loose or broken components in the blower or compressor.

- Grinding or screeching – Often a sign of motor issues or worn-out bearings.

- Whistling or hissing – May indicate duct leaks or a refrigerant leak.

- Repeated clicking – Could signal electrical problems with relays or capacitors.

If you notice persistent or unusual sounds, scheduling an inspection can prevent minor issues from escalating into costly repairs.

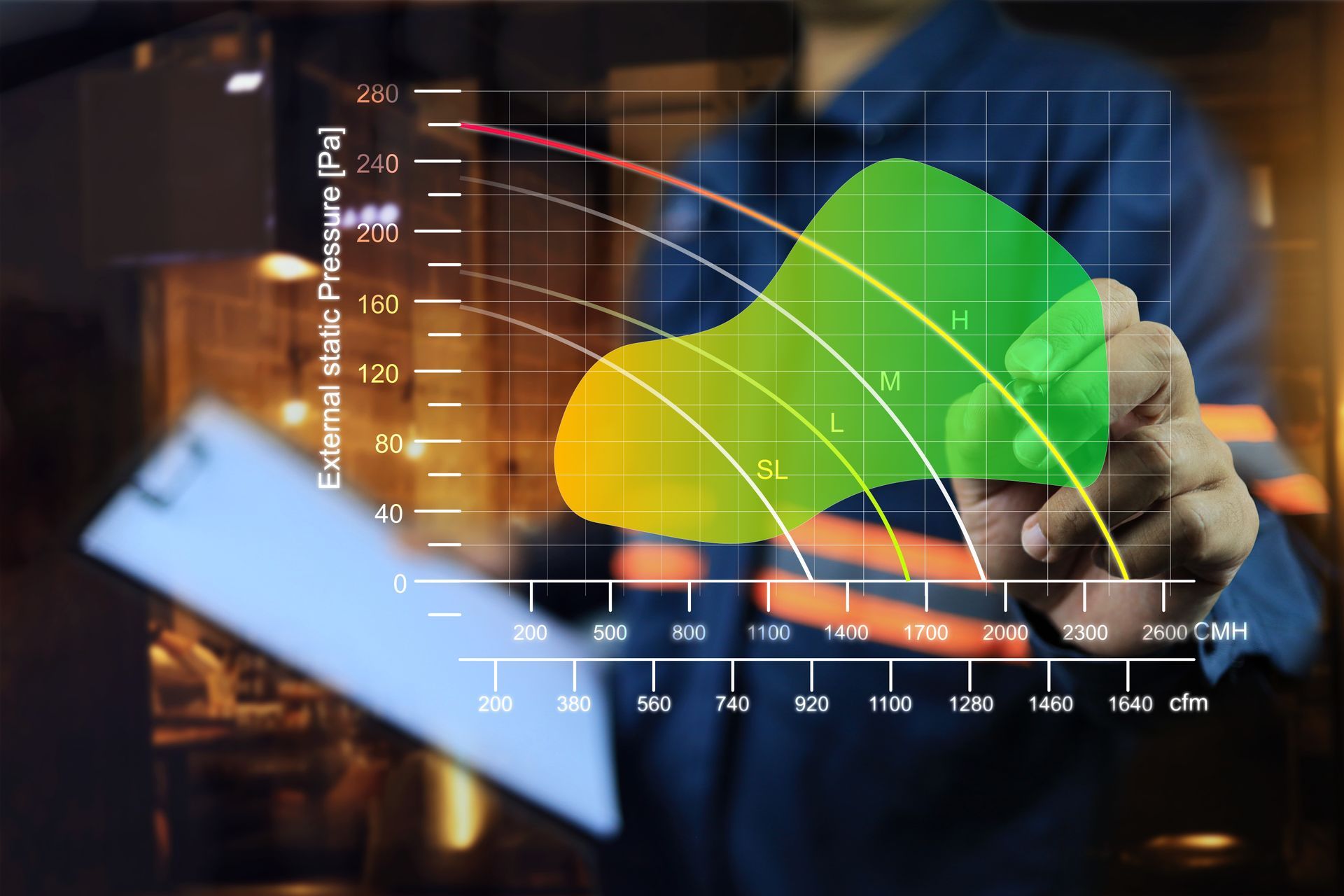

Feel for Proper Airflow and Temperature

An HVAC system should provide consistent airflow and maintain the set temperature throughout the facility. Signs of trouble include:

- Uneven heating or cooling – Hot and cold spots suggest airflow problems, duct leaks or thermostat issues.

- Weak airflow from vents – Could be due to clogged filters, blocked ducts or a failing blower motor.

- Humidity problems – If the building feels excessively humid, the system may not be dehumidifying properly, which can lead to mold growth and discomfort.

Look for Visible Warning Signs on Your HVAC Equipment

- Watch for ice buildup on coils, which may indicate low refrigerant levels or airflow restrictions.

- Excess condensation or pooling water near the unit can point to a clogged drain line or a failing condensate pump.

- Additionally, dirty or clogged filters can restrict airflow, forcing the system to work harder and reducing indoor air quality.

- Frequent tripped breakers or sudden system shutdowns could suggest electrical overloads or compressor issues.

If any of these warning signs appear, immediate attention is necessary to prevent costly repairs.

Investigate Strange Odors

Strange smells coming from your HVAC system can be an early indicator of underlying issues. Some odors are harmless, but others can point to serious mechanical or air quality concerns:

- Burning or electrical smells –

If you detect a burning odor, it could mean overheating components, such as a motor or wiring issue. A persistent electrical smell may indicate that the unit is drawing too much power or that its wiring insultation is failing.

- Musty or moldy odors –

This often signals excess moisture buildup in the ductwork, air handler or drip pans, which can lead to mold and mildew growth. Poor drainage or clogged filters can exacerbate the issue.

- Rotten egg or sulfur-like smell –

This is a major red flag, as it could indicate a natural gas leak. If this odor is present, evacuate the building immediately and contact a professional.

- Chemical or refrigerant smells – A sweet, ether-like smell may mean a refrigerant leak, which can impact system efficiency and pose health risks.

If you notice persistent or strong odors, it’s best to shut down the unit and schedule an inspection to pinpoint the cause before the issue worsens.

Monitor System Cycling

Workers who spend a significant amount of time in a commercial structure will inevitably become acclimated to its rhythms, including the sounds of the HVAC system cycling. If those cycling patterns suddenly change, despite no changes to thermostat settings or outdoor temperature, it may indicate underlying problems:

- Short cycling (turning on and off too frequently) –

This can indicate issues such as a dirty air filter, thermostat malfunctions, refrigerant leaks, or an oversized unit. Short cycling forces the system to work harder, increasing energy costs and wear on components.

- Long run times –

If your system runs much longer than usual without shutting off, it may be struggling to reach the set temperature. This could be caused by a clogged filter, leaky ductwork, low refrigerant or a failing compressor.

- System failing to turn on – If the unit doesn’t start when expected, it could be due to thermostat failures, tripped breakers, or an issue with the capacitor or ignition system.

Inspect Outdoor Components

Many HVAC problems originate outside, where the condenser unit and other external parts are exposed to dirt, debris, and weather-related wear. Facility managers should regularly check the outdoor unit for any blockages caused by leaves, dirt or other debris, as restricted airflow can cause the system to overheat. Adequate clearance around the unit is necessary for proper ventilation.

The condenser coils should also be inspected for damage or corrosion, as bent or dirty coils can impact efficiency. If you find standing water around the unit, it could indicate drainage issues or refrigerant leaks.

Routine visual inspections can help catch small issues before they turn into major system failures, ensuring reliable performance and a longer lifespan for your commercial HVAC unit.

Monitor Energy Usage and Thermostat Performance

An unexpected spike in energy costs could signal HVAC inefficiencies. If a building’s energy bills are climbing despite normal usage, the system may be running harder than necessary due to dirty components, refrigerant issues or duct leaks.

The first thing you should check after noticing unusual changes in your energy bills is the building’s thermostat. If there’s a noticeable discrepancy between the actual temperature inside and the temperature set on the thermostat, it may require recalibration or replacement.

Regularly monitoring energy consumption and thermostat performance can help facility managers spot inefficiencies before they result in higher operational costs.

When to Schedule Professional Commercial HVAC Maintenance

Regular maintenance can prevent most HVAC issues before they impact comfort or efficiency. If you notice any of the above warning signs, a professional HVAC technician can inspect the system, diagnose the issue, and recommend necessary repairs or adjustments.

By keeping an eye (and ear) on these key indicators, facility managers can ensure their commercial HVAC systems remain in top condition, reducing downtime and costly emergency repairs. Call Tom’s Commercial at 817-857-7400 if you suspect any problems with your system.