Do Building Materials Matter When It Comes to HVAC Installation?

Share

When you’re planning an HVAC upgrade or replacement, it’s easy to focus only on equipment specs and unit capacity. But there’s a major factor that often gets overlooked: your building’s construction. The materials used in your walls, roof, insulation and windows can have a huge impact on how your system performs, and whether the installation process goes smoothly.

Insulation and Envelope Quality Influence System Sizing

A building’s insulation and overall envelope efficiency directly affect how much heating and cooling power is needed. Older buildings with poor insulation or outdated construction methods often require larger or more powerful systems to achieve the same comfort levels.

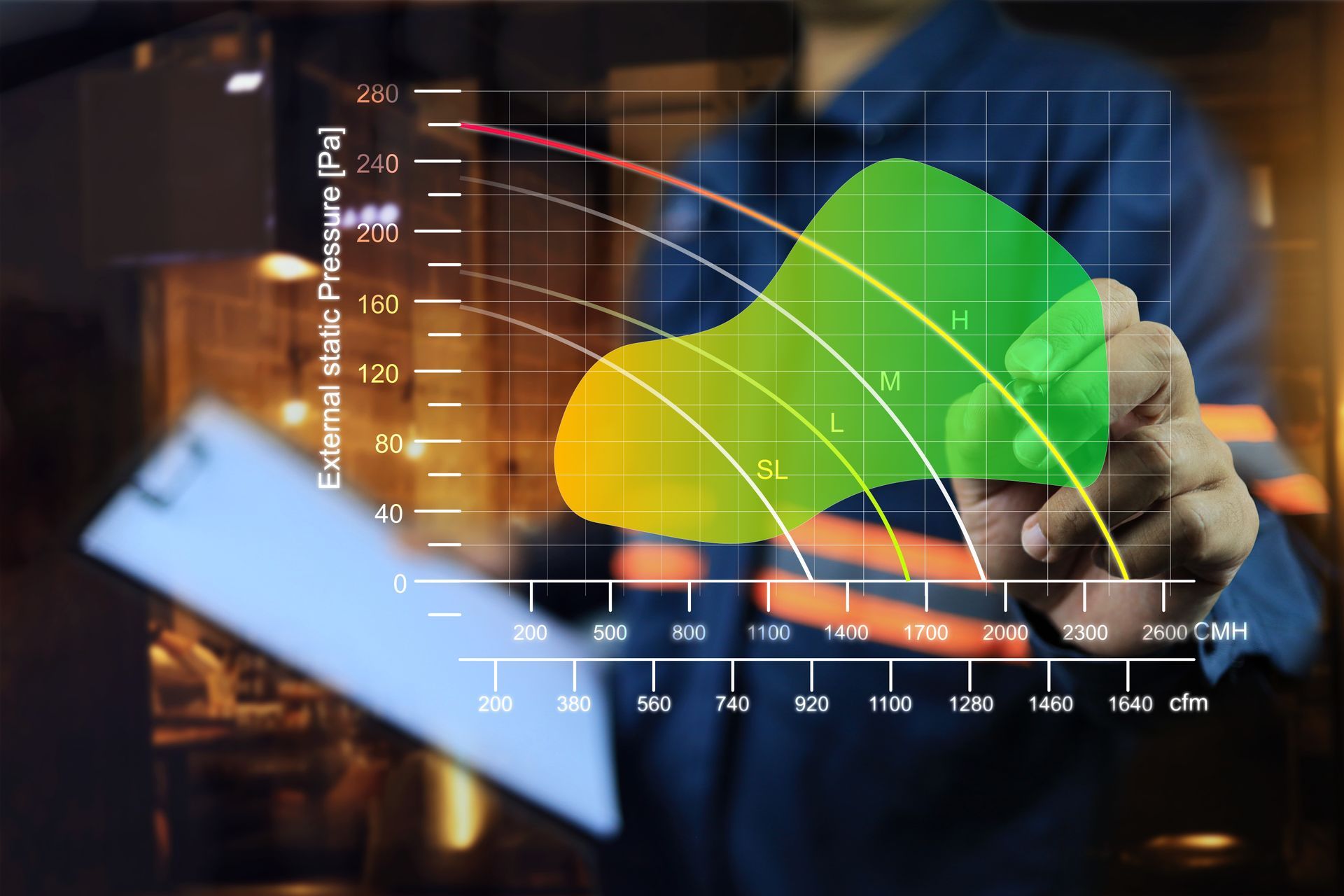

On the other hand, well-insulated structures can often get better results with smaller, more efficient units. Commercial HVAC installers should take that into account when recommending equipment, so you don’t end up with an oversized system burning more energy than necessary or an undersized one that can’t keep up.

Window Type and Placement Affect Load Balance

If your building has large windows, especially on sun-exposed walls, they’ll influence indoor temperatures more than you might expect. Single-pane glass, poor seals or a lack of shading can all contribute to excessive heat gain, especially in Texas summers. A proper HVAC design considers these factors and may include zoning strategies or additional airflow controls to prevent hot or cold spots near windowed areas.

Roofing and Wall Materials Impact Temperature Control

Metal roofs and lightweight siding can absorb and radiate heat quickly, creating a significant challenge for cooling systems. Brick or stone walls may retain heat longer, making it harder to cool down in the evenings. These characteristics all affect how your building responds to temperature changes—and need to be factored into system sizing and airflow planning.

Building Materials Can Complicate HVAC Replacement Logistics

Sometimes it’s not just about performance—it’s about getting the equipment in place. Heavy roofing materials, dense framing or older wall systems may not support modern units without reinforcement. Other times, routing ductwork through tight attic or crawlspace areas becomes difficult due to the way the building was originally constructed. Commercial HVAC companies need to review those access points ahead of time to prevent delays, safety issues or last-minute changes to the plan.

Ventilation Design Must Match Building Composition

The way a building is sealed also affects ventilation. Structures built with tighter envelopes need carefully planned ventilation to maintain indoor air quality and prevent humidity issues. Older, more porous buildings might allow unintentional air exchange, requiring system adjustments to keep air flowing properly and efficiently.

Retrofits Require Even Closer Attention to Materials

If you're upgrading or supplementing an HVAC system in an existing building, building materials become even more important. Many older commercial properties weren’t designed with today’s HVAC standards in mind. You may run into limited access for ductwork, roof structures that can’t support modern unit weights or older materials that make cutting or sealing more difficult.

Retrofit projects can stall if the installer didn’t anticipate these challenges—or worse, installed a system that couldn’t perform well due to structural limitations.

Commercial HVAC companies shouldn’t just bid based on cursory analysis; they need to look ahead at what modifications or changes might be required for proper implementation. Contractors should evaluate things like roof access, framing, insulation and how new components will integrate with your existing ductwork and layout.

Our commercial HVAC installation professionals always look for potential issues ahead of time and explain options before work begins, so there are no surprises midway through. Thorough planning saves time, avoids costly delays and ensures the new system will perform the way it’s supposed to without forcing you to drastically modify your building just to make it work.

Our Installation Teams Account for Building Materials from Day One

We’ve worked on everything from industrial warehouses and schools to churches and office buildings—and we know that the best system on paper can fall short if it’s not designed for the space it serves.

That’s why we don’t just quote a unit based on square footage. We assess how your building is built, what kind of thermal challenges it creates and how to get the equipment installed safely and effectively. If there’s a smarter way to do the job—like using a different system style or a creative install method—we’ll find it.

Call Tom’s Commercial at 817-857-7400 for a solution designed around your building.