How Control Sequence Drift Causes Heating Systems to Underperform During Peak Winter Demand

Share

The heating systems in many Arlington and Fort Worth commercial buildings often keep up just fine during cool fall mornings. But then a true North Texas cold snap hits and suddenly some zones are struggling to reach setpoint or are running flat out with little improvement.

If filter changes, setpoint tweaks and basic service don’t get a system back to normal, the problem may be deeper. One of the most frequently overlooked causes is control sequence drift, a multifaceted phenomenon that can be tough for even an experienced facility management team to diagnose on their own.

What Is Control Sequence Drift?

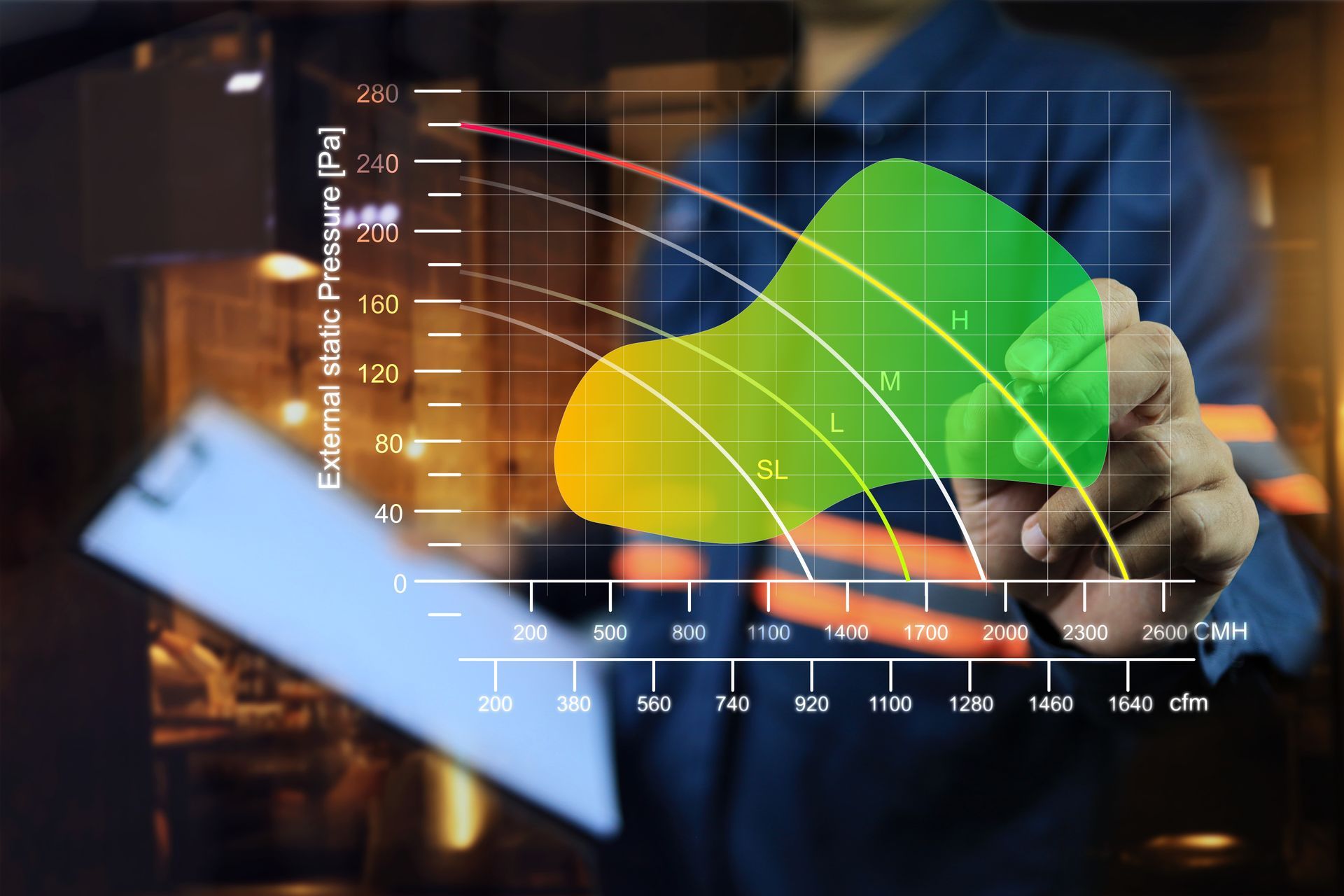

Modern commercial heating systems rely on programmed sequences to coordinate stages, manage economizers and respond to changing demand.

Whether your facility has packaged rooftop units or a full BMS-integrated plant, each component is supposed to act in sync, ramping up or down in response to actual load and outside conditions.

Sequence drift happens when the system’s actual behavior starts to diverge, sometimes subtly, sometimes dramatically, from its intended logic.

How Sequence Drift Develops in Commercial Buildings

Several factors can push a control system out of alignment over time:

- Seasonal overrides and forgotten setpoints: Quick fixes for a one-off comfort complaint are often left in place, gradually stacking up as new staff or techs make adjustments without resetting to baseline.

- Sensor drift: Even high-quality temperature, pressure or airflow sensors can lose calibration over months or years. The system may be “reading” an outdoor temp that’s several degrees off or staging based on a faulty signal.

- Software updates and resets: Routine updates or power cycles can reset certain defaults, quietly undoing previous optimization or introducing small mismatches.

- Multiple hands on the system: Different vendors, contractors or operators may make uncoordinated changes, resulting in conflicting logic or setpoints.

The Hidden Consequences During Peak Demand

In mild weather, sequence drift is easy to miss. But as load rises and margins tighten, it can lead to:

- Misaligned staging: Heating stages activate out of order or not at all, leaving capacity unused when you need it most.

- Economizer interference: A misprogrammed or drifting economizer can pull in more outdoor air than intended, forcing the system to reheat cold outside air instead of recirculating warm return air.

- Zone imbalance and comfort complaints: Some areas may overheat while others never catch up, leading to calls from tenants or facility staff.

- Short cycling or excessive runtime: Systems that can’t satisfy demand may run longer, cycle more often or rack up utility bills and wear.

Why Cold Snaps Make the Problem Worse

On mild days, your heating plant has room to absorb small errors in sequence or staging. But when a true cold snap hits, the difference between a perfectly coordinated system and one with sequence drift can mean the difference between stable comfort and widespread complaints.

Drifting logic doesn’t have the capacity to catch up or recover quickly. Issues that were only “mild annoyances” last month may become urgent failures when outside temperatures plunge.

Diagnosing and Correcting Sequence Drift

Identifying sequence drift isn’t always straightforward. Being able to accurately analyze trend logs, system data and BMS reports is critical. Facility managers or commercial HVAC technicians can use that data to identify unexpected staging, inconsistent temperature readings or economizer dampers opening at the wrong time.

Calibrating sensors, reviewing setpoints and testing control sequences under load can help pinpoint where the drift has crept in.

Preventing Future Sequence Drift Issues in Commercial Facilities in Arlington and Fort Worth

The best way to avoid sequence drift headaches is with periodic review and calibration. An annual sequence check as part of your winter startup can catch small misalignments before they become major issues.

Make sure sensor calibrations are scheduled, and that access to controls and programming is clearly documented to avoid conflicting changes by different techs or operators.

If your heating system isn’t keeping up during cold snaps, or if you’re seeing persistent comfort or efficiency issues, call Tom’s Commercial at (817) 857‑7400. Our team specializes in diagnostics, control strategy review and repairs for commercial heating systems across Arlington and Fort Worth.