The Operational Costs of Ignoring Air Leakage in Multistory Commercial Buildings During Cold Spells

Share

Air leakage in multistory commercial buildings isn’t limited to drafty entryways or aging window frames. During cold spells, warm air escaping through upper floors, shafts and roof penetrations can create pressure imbalances that pull cold air deep into the building, even in interior spaces with no operable windows or exterior doors. These leaks show up as uneven heating, persistent drafts and systems that struggle to keep up despite adequate equipment and routine maintenance.

The Stack Effect and Pressure Imbalances

Stack effect is a powerful force in tall buildings during cold weather. Warm indoor air rises and escapes through roof hatches, elevator shafts or upper-floor leaks, creating negative pressure that draws cold outside air in at lower levels.

This constant movement of air pushes your heating system to work harder, often running longer hours just to maintain setpoints. As a result, floors near the top can overheat while ground-level zones remain uncomfortably chilly.

Common Sources of Air Leakage in Commercial Structures

- Unsealed Doorways: Exterior doors without proper weatherstripping are a major entry point for cold air, especially if automatic closers aren’t working or doors are propped open for deliveries.

- Loading Docks and Access Bays: Dock doors and freight access points that don’t close fully create constant air leaks. In busy buildings, these areas may be open for long periods, compounding the loss.

- Utility and Pipe Penetrations: Openings for electrical, plumbing or IT lines often run through walls, ceilings and mechanical rooms. If not sealed tightly, they can act as small chimneys for air leakage.

- Elevator Shafts and Stairwells: These vertical shafts can act as highways for stack effect, drawing warm air up and out while pulling cold air into lower floors, especially when doors don’t seal tightly.

- Roof Hatches and Mechanical Penthouse Access: Poorly sealed roof hatches or penthouse access points are frequent trouble spots in multistory buildings. Warm air naturally rises and can escape quickly through these openings.

- Window Frames and Curtain Wall Gaps: Older buildings or those with aging window systems often have leaky frames, failing gaskets or loose panels. Even small cracks can allow significant heat loss during a cold spell.

- After-Hours Modifications: Temporary cables, event access doors or construction cutouts made for short-term needs often get overlooked during regular maintenance, leaving unsealed gaps.

Real-World Impact on Heating Loads and Utility Costs

A half-inch gap under a door is equivalent to a fist-sized hole in the wall in terms of air leakage. During cold snaps, these losses are magnified. In severe cases, a facility’s HVAC system may run non-stop, increasing both energy bills and wear on key components.

Persistent air leakage can also lead to short cycling, temperature swings between floors and more dissatisfied occupants and tenants.

Diagnosing and Quantifying the Problem

Finding air leaks in multistory commercial buildings usually takes more than a walk-through. Professional diagnostics often include thermal imaging to spot cold spots along exterior walls, rooflines or around penetrations.

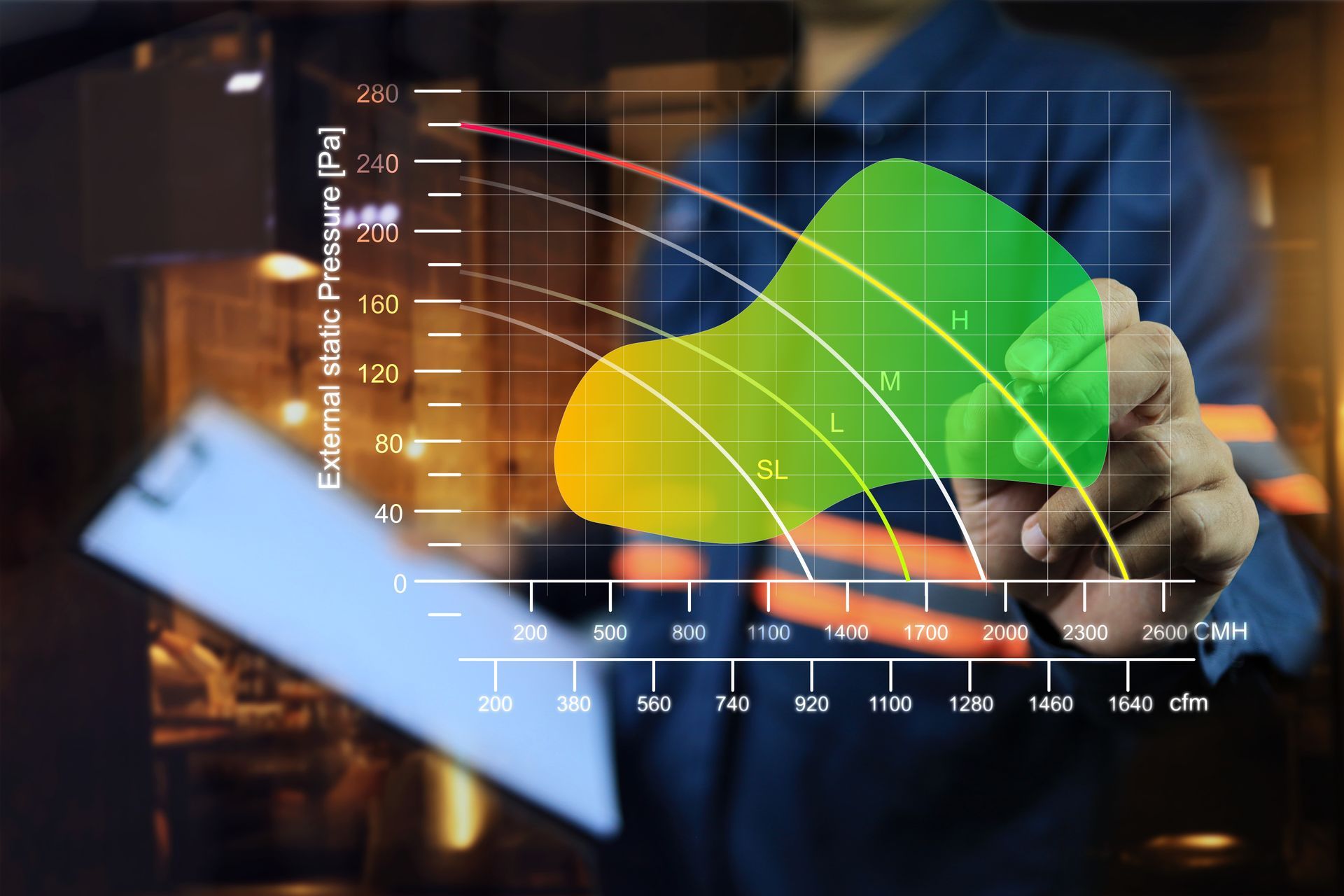

Building pressure measurements with handheld manometers at doors, stairwells and shafts can help identify zones under negative or positive pressure.

Facility teams can identify places with unexplained drafts, persistent cold spots and wide temperature swings between floors ahead of time to narrow down where problems are located.

Building Sealing and Balancing, Along With Consistent Maintenance, Help Prevent Common Winter Heating Challenges

The most effective approach to preventing air leaks is to prioritize sealing the largest and most accessible leaks first. Exterior doors, roof penetrations and mechanical shafts often yield the biggest returns.

Coordinating these sealing efforts with HVAC system balancing and controls adjustments helps ensure that air isn’t being pushed through new “weak spots” after the initial fixes.

Regular reviews and inspections, especially after any remodel or major equipment change, are essential for keeping the building envelope tight and energy bills under control.

If you’re concerned about air leakage or escalating heating costs in your commercial building, Tom’s Commercial offers comprehensive diagnostics and sealing services to keep your systems running efficiently, even during the harshest North Texas winters. Call (817) 857‑7400 to schedule a consultation.