Why Commercial Boilers Lose Efficiency Midseason Even After a Fall Tune Up

Share

It’s a common frustration for facility managers and building operators. The boiler passes its fall tune‑up, startup looks clean and early heating season performance seems fine. Then, halfway through winter, fuel usage creeps up, recovery times slow and comfort complaints start rolling in.

At that point, it’s tempting to assume the boiler itself is failing. The good news is that, in many of these mid-winter performance drop-off scenarios, it’s more about real-world operating conditions than the boiler itself.

What a Fall Tune‑Up Does and Doesn’t Address

A fall boiler tune‑up typically focuses on combustion checks, safety controls, startup operation and visible maintenance items. Those steps are essential, but they’re largely static snapshots of boiler performance.

A fall tune-up won’t always reveal issues that develop once the boiler is running longer hours, cycling more frequently or interacting with other system components under real mid-winter demand conditions. It’s not uncommon for inefficiencies to emerge only after weeks of high-demand operation.

Water Quality Issues That Show Up Under Load

Water quality is one of the most common contributors to declining boiler efficiency as winter progresses. Scale buildup, corrosion products and sludge reduce heat transfer efficiency and restrict flow through the heat exchanger. Even modest deposits can force the boiler to burn more fuel to deliver the same amount of heat. These issues may not be obvious during startup but become increasingly problematic as runtime increases and water temperatures remain elevated for longer stretches.

Part‑Load Operation and Short Cycling

Most commercial boilers are sized for design conditions that occur only during the coldest days of the year. For much of the season, the boiler operates at part load. If staging, modulation or turndown aren’t well matched to actual demand, efficiency can drop, short cycling can become more frequent and the system may struggle to reach steady‑state operation.

Over time, this increases fuel consumption and accelerates wear on burners, controls and ignition components.

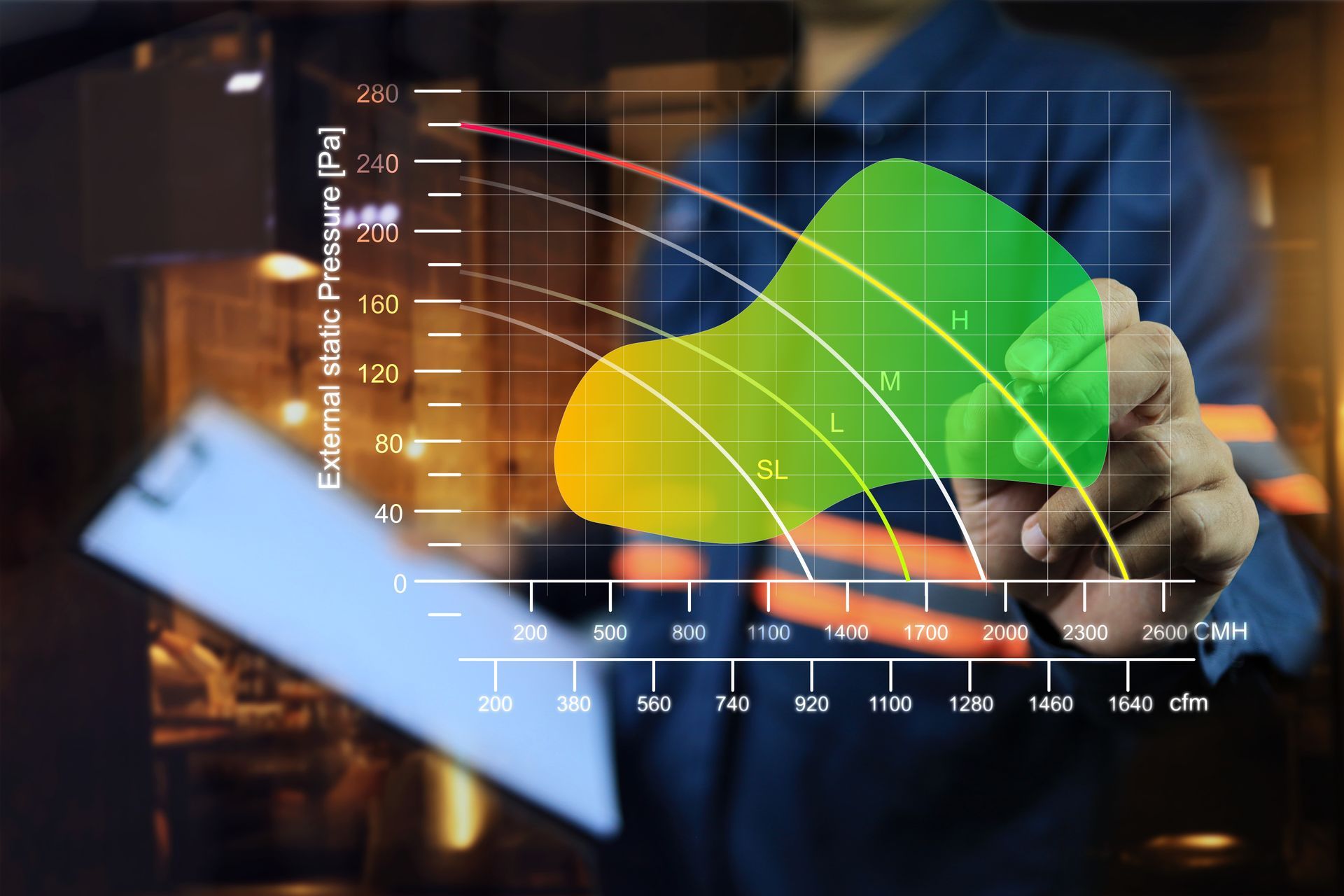

Pump Curves and Flow Mismatches

Boilers depend on proper water flow to maintain efficiency and protect internal components. As zones open and close throughout winter, actual system flow often deviates from design assumptions. Pumps that are oversized, undersized or mismatched to the current load can reduce delta‑T across the boiler, limiting heat transfer and increasing runtime.

These issues rarely surface during fall startup but become more pronounced midseason when multiple zones demand heat simultaneously.

Controls and Sensor Accuracy Matter More Than Expected

Commercial boilers rely heavily on accurate temperature and flow sensing to regulate firing rates and staging. Sensor drift, failed probes or poorly placed sensors can quietly degrade performance. If the boiler is operating based on incorrect data, it may fire longer than necessary or fail to respond properly to load changes.

Control logic that hasn’t been reviewed since installation can also contribute to inefficiencies once operating conditions shift deeper into winter.

Signs Your Boiler Is Losing Efficiency

Midseason efficiency loss often shows up as longer warm‑up times, uneven heating across the building, rising fuel bills or increased cycling. In some cases, operators notice new noises, higher stack temperatures or boiler lockouts that weren’t present earlier in the season.

These symptoms point to system‑level issues rather than isolated equipment failure.

Why Midseason Diagnostics Matter for Boiler Performance in Arlington and Fort Worth

Waiting until a boiler fails outright is rarely the most cost‑effective approach. Midseason performance checks allow technicians to evaluate water quality, verify flow rates, review control behavior and identify inefficiencies before they turn into major repairs. Addressing these issues early can stabilize performance, reduce operating costs and extend equipment life.

If your commercial boiler isn’t delivering the efficiency or performance you expected this winter, Tom’s Commercial can help. For expert boiler diagnostics, repair and system optimization in Arlington and Fort Worth, call Tom’s Commercial at (817) 857‑7400.